Pad Printing – one of the most common marking methods. It involves layering ink by stamping ( a pad) . The major advantage is to be applied onto various kinds and patterns of surfaces such as plastic, rubber, glass, metal or even fabric. The size of print is limited by the size of the pad which is approximately 5cm per 5 cm.

Screen Printing – one of the direct printing methods. The print is made by pressing the printing ink via frame onto a given surface. The advantage is the wide area of marking surface, best for fabric products e.g. textiles, bags, umbrellas. The effect is highly eye-catching, durable and coulourful imprint.

Thermal Transfer Printing – a method using hot-stamping a logo into materials. The logotype is being printed on a special, thermal paper. Then it is transferred onto the product with high temperature.

It is recommended for reproduction of multicoloured print including little details in pattern.

Dye-sublimation printing – it is the most effective labelling technique for photographic output.

Dye-sublimation printing method is strongly recommended to 100% polyester products in white colour.

Doming – this technique enables printing 3D effects by covering the label with polyurethane liquid that flows to the edge of the label which is then hardening into a clear dome. It is flexible, very long-lasting and efficient labelling method.

Embossing – a method where logos are shaped on leather and eco-leather objects that are being exposed to suitable temperature and pressure. The matrix for labelling is made separately for every single logo. It may be used several times though. Application of proper foil makes it possible to emboss in colour.

Machine Embroidery – a very long-lasting and efficient labelling method proving perfect for textiles. Using computer-controlled embroidery machines one may get extraordinary precision of sewing. Each order takes to employ an individual programme and its price depends on the number of needle strikes or so-called piercing necessary for a logo to be created.

Laser Engraving – one of the most permanent labelling methods. This method engages a laser beam which removes the outer layer of ornamented items with extreme accuracy. The colours used for labelling are descritionary, though dependent on the kind of material that an object is made of. Laser engravering is applicable to metal, leather, wood, glass and plastic.

UV DIGITAL PRINTING – UV printing is a direct printing method that involves labelling products with the use of a computer-controlled UV printing machine. The digital printing provides full coloured imprints of high quality and durability. Afterwards, the imprints are being stiffened, which makes them become resistant to water, humidity and the sunlight. The method is perfect for minor orders or those intended as bigger projects

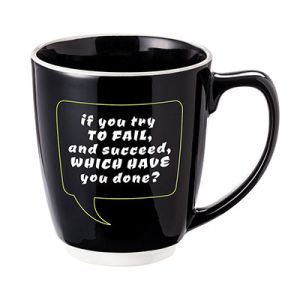

Transfer Printing – unlike direct printing, transfer printing involves printing the design onto carbonated paper which is then transferred by pressing onto the ceramic piece. In the next stage, a product is exposed to the heating process in the temperature of ca. 800 degress Celsius. Transfer printing makes it possible to customize and ornament convex and concave surfaces, that is on the inside, the bottom and the handle of a mug in a way unachievable for other methods.

Sand-blast Cleaning (Sensitive Touch) – a technique of labeling providing a 3D effect. It takes to carve a chosen pattern into enamel of a product. One can sandblast stained ceramics as much as stain ready-made ornamented ceramics.

Art Print – a sublimation printing process that provides photographic quality of ornamentation with high resolution and bright colours. It takes for the design to be printed on paper and stuck onto a mug. The item is then heated in low temperature of 180 degrees Celsius. This type of printing is recommended when it comes to minor orders. Labelling with the use of Art Print technology is yet to be made resistant to dishwashing! The label is possible to be made on few chosen models.

Magic Mug – a printing technique which allows to get photographic quality of ornamentation with high resolution and bright colours. The print is virtually invisible, though it emerges when a mug is warmed up with hot liquid inside. The MAGIC technique takes for the design to be printed on paper and stuck onto a mug. The item is then heated in low temperature of 180 degrees Celsius.